Siemens’ Simulator To Streamline Axial Flux Motor Design in EVs

Siemens’ latest multi-disciplinary software promises to accelerate design innovation of reliable compact motors for electric vehicles.

The quest for sustainable transportation and a greener environment has sparked the global demand for electric vehicles (EVs). Yet, the EV industry grapples with significant challenges and complexities in meeting rapidly evolving customer demands. Furthermore, constraints in the supply chain, coupled with design hurdles, notably impede the pace of innovation.

Siemens has unveiled a multi-disciplinary Simcenter E-Machine Design software to reduce reliance on physical prototyping and tackle challenges in designing thermally efficient and compact motors for EVs. This article examines the challenges of designing axial flux motors and how the product addresses them.

Illustration of Siemens Simcenter electric vehicle design. Image used courtesy of Siemens

Challenges in Electric Vehicle Design

Developing efficient and reliable motors is critical for meeting the demands of increasingly discerning customers and staying competitive in a rapidly evolving market. In an EV, the motor's efficiency, power, and torque density directly influence the vehicle's mileage, while its cost ranks second only to the battery's.

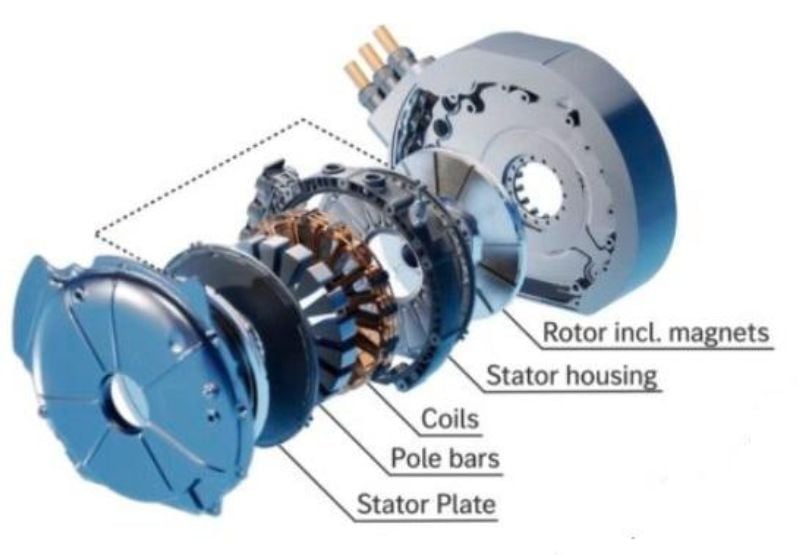

Anatomy of an axial flux motor. Image used courtesy of Mercedes Benz

Axial flux motors are an emerging form of EV motor that promises increased range thanks to a combination of compact size and increased power and torque densities. In an axial flux motor, the magnetic flux flows parallel to the motor's axis. Engineers working on these motors encounter difficulties in heat dissipation and accommodating the motor’s required air gap, given the motor’s compact size and complexity.

In the bigger picture, designing axial flux motors involves conceptual design, electromagnetic simulation, thermal management, prototyping, performance testing, and iterative refinement. This multifaceted approach necessitates increased development costs and long times to market, which hinder manufacturers from keeping up with market requirements. Considering the circumstances, it is imperative to utilize advanced simulation tools and prototyping methods, streamline the design process, and capitalize on diverse expertise.

Innovating Electric Vehicle Motor Design

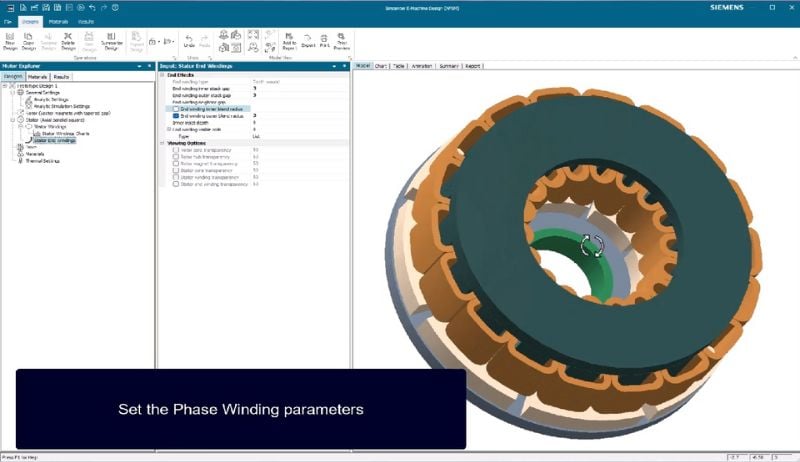

Siemens addressed the challenges in axial flux motor design for EVs by introducing the Simcenter E-Machine Design software. This software integrates electromagnetic and thermal simulation, facilitating accurate prediction of electrical machine performance.

Simcenter E-Machine Design offers unparalleled versatility, allowing users to choose from different EMAG experiments for precise performance data collection at various design stages. Based on a template-driven approach to automation, Simcenter aims to streamline experimentation and reduce reliance on physical prototypes. The tool provides a comprehensive solution for evaluating machine performance under operating conditions and simulates crucial aspects like motor housing, transmission, noise, vibration, and harshness performance.

A glimpse of Simcenter E-Machine Design software environment. Image used courtesy of Siemens

A notable offering of the tool is its smart virtual sensing feature, which enables test engineers to replicate immeasurable conditions by integrating simulation with physical testing. It allows physical test teams to place virtual sensors in challenging locations or complex geometries, facilitating real-time data collection alongside physical tests. By combining data from physical strain gauges with a reduced-order model, engineers can compute operational loading conditions and obtain results from otherwise unreachable virtual sensors.

Simcenter 3D also integrates design space exploration, automating parameter adjustments, model updates, and result reviews. This facilitates tradeoff analysis and optimization without the need for manual input.

Electric Vehicles Transforming the Future

By offering a path toward improved efficiency and reliability in next-generation motor designs, Siemens’ Simcenter E-Machine Design paves the way for enhanced electric vehicle performance and sustainability. As electric vehicles become increasingly prevalent worldwide, technologies like Simcenter have the potential to play a vital role in reducing carbon emissions and shaping a sustainable future.